South Australian manufacturer Accurate Dosing Systems (ADS) has landed a key contract to create and service a purpose-built robot for Firmenich, a privately-owned fragrance and flavour company in Belgium.

Headquartered at the Tonsley Innovation District, ADS will develop a hi-tech robot – which is being shipped to Firmenich’s creation laboratory later this year – to automate the process of measuring hundreds of flavouring solutions.

The outcomes will be used in soups, coffee, yoghurt, and morning cereals in order to modify its recipes and flavour profiles, the SA government said in a media release.

The revolutionary robot, which is claimed as the first of its type at Firmenich, will also use hybrid technology to mix perfume and flavour formulations on the device in minutes as opposed to hours for maximum efficiency.

The state government said that only five companies worldwide, including ADS, provide this specialised dosing technology, making it well-positioned to give South Australia a larger share of the USD 24 billion (AUD 36 billion) flavour and fragrance market.

Trade and Investment Minister Nick Champion noted that as more regional businesses, like Accurate Dosing Systems, experience global success, South Australia’s growing reputation for advanced manufacturing is strengthened.

He added that this new partnership is another example of successful tech commercialisation and further demonstrates why South Australia is a wise place to invest in.

“It’s great to see this local company now using the Precinct’s collaborative connections, entrepreneurial culture and global networks to expand its influence and reach around the world,” he said.

Masoud Bahmai, ADS co-founder and managing director, indicated that by providing an optimised combination, the company is now able to satisfy the needs of mid-to-large enterprises, which frequently require processing speed and significant levels of automation.

“We are in the right place. We are surrounded by manufacturing technology companies, so it’s easier for us to attract staff with higher skills because it’s a vibrant and exciting environment with opportunities for collaboration,” Bahmai noted.

In May last year, ADS relocated to the Tonsley Innovation District, which is funded by the Malinauskas Labor Government, accelerating the development of its technologies.

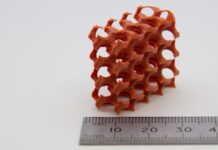

The state government said it used the relocation to take advantage of the district’s substantial advanced manufacturing skills, purchasing equipment from Phoenix Contact and Rockwell Automation on-site and working with Flinders University for 3D printing services.