Professional Documents

Culture Documents

Sustainable Building Project Delivery in The Era of 4th Industrial Revolution

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sustainable Building Project Delivery in The Era of 4th Industrial Revolution

Copyright:

Available Formats

Volume 8, Issue 4, April 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Sustainable Building Project Delivery in the Era of

4th Industrial Revolution

TPL. Adeniyi, JoshuaOlu¹; Tpl. Odogiyon Agunloye H.²

1&2:

Department of Urban and Regional Planning, Rufus Giwa Polytechnic, Owo, Nigeria.

Ezekiel Ufuoma Lucky³

3

Department of Urban & Regional Planning,

Federal University of Technology, Akure, Nigeria

Abstract:- Harnessing the fourth industrial revolution in the 21st century as a result of growing interconnectedness

for sustainable building projects requires digitization, and intelligent automation. The word has been widely used

automation, and the increased use of Information and in scientific literature, and World Economic Forum founder

Communications Technology (ICT). The construction and executive chairman Klaus Schwab popularized it in

industry compared to other industries seems to lag 2015 ( Bai, et al.2020). By obfuscating the distinctions

behind in incorporating these innovative technologies. between physical, digital, and biological entities,

However, there are numerous challenges in technological advance has discovered new ways to

implementing and engaging the use of technology in the demonstrate their capabilities. In addition to modern

construction industry. A review is done to identify the procedures supporting every industry component, the

issues underlining the adoption of technology in the revolution also promotes sustainability (Colombo, et al.

construction industry. 2014), of which renewable energy and energy efficiency are

two key elements (Lee, et al. 2018). Although the

This study shows that the critical factor affecting implementation is challenging, renewable energy still

the successful implementation is the lack of awareness accounts for 19.2% of consumption and is impacted by

and technical know-how. However, the study also technological advancements in the sector (Carvalho, et al

highlights that there are numerous opportunities in the 2018). The Industrial Revolution (IR) 4.0) aims for a

future if critical steps are taken to bridge the gap in workable and sustainable manufacturing system and has a

technical knowledge for sustainable building projects higher level of complexity for integrating the production and

whilst adopting the technology of the fourth industrial product processes, where it becomes a part of the

revolution. sustainable system (Carvalho, et al 2018). When adopting

Industry 4.0 to create sustainable industries, all three aspects

Keywords:- Sustainability; Industrial Revolution; of sustainability—social, economic, and environmental—are

Information and Communication Technology; and valued and used for long-term competitiveness (Carvalho, et

Construction. al 2018). For both short- and long-term impacts on

I. INTRODUCTION sustainability, consideration of tactical, operational, and

strategic dimensions is crucial. By implementing 4IR, which

Since the 1700s, when the era of industrialization increases product quality while reducing time-to-market and

began, each industrial revolution has contributed improving operational performance, the benefits of 4IR are

significantly to the advancement of modern development. evident. Despite the many advantages offered by the other

The introduction of mechanical looms, which supplanted the industries, the building industry has been reluctant to adopt

agricultural industries and significantly improved the these ideas. Construction industry resistance to adopting IR

economic structure, occurred in the 1700s (Philbeck, & 4.0 was evident even in the complicated construction

Davis, 2018). These looms were powered by water and environment (Alaloul et al. 2020). Whereas the entire value

steam on mechanical machinery. The introduction of chain of construction involves numerous dispersed

electrical energy, which led to the establishment of the mass counterparts from all levels with a variety of backgrounds to

production system, sparked the Second Industrial cater to the unique needs of each project. Small and

Revolution in the 1870s (Alaloul, et al. 2020) These medium-sized businesses (SMEs) are now less able to invest

revolutions were dependent on how much more capable in new technologies due to the phenomenon's increased

humans were. The Third Industrial Revolution, brought on complexity in implementation.

by the development of electronics, took place in the 1970s.

The term "Digital Revolution" describes the technological Despite the obvious advantages that IR 4.0 principles

advancement from analog electronic and mechanical devices provide, the construction industry is still having trouble

to the current state of digital technology (Alaloul, et al. implementing them. There are a few difficulties in the

2020). The Fourth Industrial Revolution (IR 4.0) is now construction sector that lead to incompatibility. Complexity,

being constructed upon the Digital Revolution, in which ambiguity, a disjointed supply chain, short-term thinking,

people and technology are interconnected. The Fourth and culture are among the issues, according to Oesterreich

Industrial Revolution, also known as Industry 4.0, is a and Teuteberg (Oesterreich, &Teuteberg, 2016). The

concept that describes the significant changes in technology, engagement of numerous stakeholders makes construction

industries, and societal patterns and processes that will occur projects difficult, making them special. A project's degree of

IJISRT23APR016 www.ijisrt.com 2445

Volume 8, Issue 4, April 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

uncertainty is also determined by the project's unpredictable There is also a need for improvements in performance in

environment and its added complexities. Whereas the short- construction that have the potential to improve a perceived

term nature of building projects is a barrier to innovation, need for the implementation of Industry 4.0 (Keogh, &

the supply chain is fragmented and construction businesses' Smallwood, 2021).

short-term mindset has constrained their capacities. Whereas

the construction industry's culture is infamous for its slow- Taher (2021) states that The adoption of IR 4.0 within

to-adapt methods. the construction sector would boost performance on par with

that of its competitors in the industrial and automotive

II. OBJECTIVE OF THE STUDY sectors. Industry 4.0 must be embraced since it is the

direction of the future. Even on the construction site,

This study seeks to ascertain the: digitization is the only option. Construction needs to catch

Awareness and utilization rate of technology in building up. According to a study on the impact of 4IR on developing

in the 4th industrial revolution. nations, Industry 4.0 may make it possible for these nations

Challenges in deploying technologies of the fourth to take a larger share of the global manufacturing value

industrial revolution in construction. chain (Hopali, &Vayvay. 2018).

A. Scope of the Study An article that examines the applicability of the major

The construction industry's scope of work is broad and Industry 4.0 technologies of a digital twin, robotics,

includes everything from building infrastructure to automation, building information management, sensors,

residential, commercial, and industrial projects. The wearables, and industrial networking to the construction

industry's contribution to a nation's Gross Domestic Product industry. To fully realize the benefits of Industry 4.0, it is

is more significant (GDP). The construction industry stated that Industrial connection is a crucial component. This

generates over US$10 trillion in total yearly sales, US$3.6 ensures that all technologies are integrated. In addition, the

trillion in added value, and contributes roughly 6% of the article outlines a research agenda for the adoption of

global GDP, according to the World Economic Forum Industry 4.0 technologies in the construction industry, a

(WEF) [1]. Additionally, it represents more than 8% of GDP three-phase use of intelligent assets from the point of

in underdeveloped countries and roughly 5% of GDP overall manufacture to after construction, and a four-stage R&D

in affluent nations. (Keogh, & Smallwood, 2021). This process for the application of smart wearables in a digitally

study is concentrated on investigating key elements enhanced construction site. Building components might be

influencing the effective adoption of 4 IR in the construction used in three stages as intelligent assets, creating a new real-

industry. time and context-aware data stream that could be used to

communicate with both workers and automated industrial

B. Significance of the Study processes in a digital twin environment. Machines and

This study looks at the potential problems faced by goods should be able to connect with and learn from one

construction businesses that want to use modern another thanks to faster processing, smarter tools, smaller

technologies to further their goals and remain competitive in sensors, and lower data storage and transmission costs

both domestic and international markets. It provides an (Turner, et al.2020).

overview of Industry 4.0 and its primary technologies as

they apply to the construction industry. Knowledge of the The conventional nature of the methodologies used in

most recent technologies empowers businesses with the construction industry's activities and the low use of ICT

excellent management vision. The second advantage of this are what define these activities. The quality of the resulting

piece is that it can assist companies in assessing the level of infrastructure is thus in doubt, which has an impact on the

digitization of their processes. Kids can now understand that general performance of the construction industry [17].

combining two of these technologies can be more However, the use of technology to deal with these issues is

advantageous in other ways. growing. According to research done in the construction

sector in the United Kingdom in 2019, 75% of construction

III. LITERATURE REVIEW businesses reported using file-sharing applications to share

and access designs, up from 52% in 2018 (Keogh, &

A study by Keogh, & Smallwood reviews that,

Smallwood, 2021). Only a small percentage of responders

Construction still faces several difficulties, including

(7%) use technology to oversee the entire procedure.

outdated processes and practices, adhering to regulations,

Furthermore, there is a significant gap between businesses

data collection and recording, monitoring, a lack of

that approach new technology expenditures strategically and

competent labor, and a decline in enthusiasm for working in

those that do so on an ad hoc basis: 26% of businesses lack a

the sector. Then, difficulties are encountered regarding

strategy, while 36% of businesses merely invest on an as-

performance with the project's cost, environment, health and

needed basis.

safety, productivity, quality, and schedule limits. In light of

the difficulties and the arrival of Industry 4.0, research was The industry is moving toward digitization and

carried out to ascertain the difficulties encountered, project including technology in the construction process. The

performance to the parameters, and the potential construction industry should aggressively adopt relevant

contribution of Industry 4.0 to overcome the difficulties. software or computer systems that can communicate and

They concluded that there is a need for interventions to utilize information, such as BIM, where applicable.

increase awareness and to integrate such technologies into Accordingly, they should incorporate off-site fabrication,

built environment/construction education and training.

IJISRT23APR016 www.ijisrt.com 2446

Volume 8, Issue 4, April 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

prefabrication, pre-assembly, modularization, and used to analyze the gathered data for validity and reliability

demonstrative installations into their building processes (Hu, of gathered data.

& Liu, 2016)). According to Autodesk & CIOB (Keogh, &

Smallwood, 2021), successful organizations will be those Average Index (AI) The AI method is used to evaluate

whose executives pursue measures to lower adoption the influencing factors and identify the most critical factor in

barriers and integrate digital technologies into their IR 4.0 having a higher impact on the construction industry.

corporate strategies.

The study was conducted using the Six Sigma Quality

IV. EMPIRICAL REVIEW Initiative method ( Define, Measure, Analyze, Improve and

Control)

There are numerous studies on sustainable building

projects in the 4th industrial revolution. According to the The AI equation is as described below:

World Economic Forum in conjunction with PWC (2017). Average Index AI ð Þ¼ PðWnÞ N ð1Þ

They surveyed over 50 countries with descriptive statistics

and analysis. Their findings were that the 4tth industrial where W: scale weightage from 1 to 5, given to each

revolution technologies can potentially aid transparency and factor by respondents;

projection in risk assessment, mitigations, and responses. n: frequency of respondents,

Technologies like AI and IoT can be deployed to N: total number of respondents.

communicate and predict future shocks on the go and

technologies like 3D printing can be deployed to enhance The classifications of the rating scales are: 1 =

the rebuilding of urban infrastructure making it more Strongly Disagree (1.0 Average Index < 1.5), 2 = Disagree

resilient and with a lower ecological footprint. (1.5 Average Index < 2.5) 3 = Neutral (2.5 Average Index <

3.5), 4 = Agree (3.5 Average Index < 4.5), 5 = Strongly

V. METHODOLOGY AND FINDINGS Agree (4.5 Average Index 5.0).

Because we utilized primary data for the research, an Relative Importance Index (RII)

ex post facto research design was adopted since the data

already exists and we will not carry out any further The AI equation is as described below:

iterations on the data.For this study questionnaires were Relative Importance Index RII ð Þ¼

distributed to multiple construction companies, PW

Questionnaires were distributed by E-mail and hard A N ð2Þ

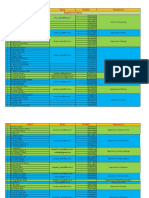

copies.Table 1 represents the demographic data of the where

respondents. W: scale weightage from 1 to 5, given to each factor

by

For this study, MS Excel was utilized for Average respondents,

Index (AI) and Relative Importance Index (RII), SPSS was A: highest weightage is given,

N: total number of respondents.

VI. RESULTS AND DISCUSSION

Descriptive Statistics

Table 1: Demographic Summary of Respondents

Source: Authors Survey results

IJISRT23APR016 www.ijisrt.com 2447

Volume 8, Issue 4, April 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

53% of respondents do not have an awareness of the consultants while the remaining 20% were service providers

use of IR 4.0 technologies in the construction industry, and Government officials.

while 34% have some exposure due to their working

experience. However, the remaining 13% of respondents are Although the 13% of respondents who replied may be,

not comfortable with the technology used and are listed as after being shown a list of IR 4.0-related technologies as

the technology related to IR 4.0. The distribution of listed in the Table.2, positively affirmed that they have been

companies amongst respondents profiles 41% of exposed to these technologies. This brings up to 47% of the

respondents as contractors, 15% of respondents as sample who are aware of the technologies of the fourth

developers,11% as client service managers, and 13% as industrial revolution.

Table 2: Summary of IR 4.0-related technology

Fig. 1: Industry-related technologies and concepts

As listed in fig.1 47% of the respondents who Given the list of technologies, by verifying and

identified as being exposed to IR 4.0-related technologies, identifying the IR 4.0-related technologies and concepts. the

identified Social Media and Building Information Modeling data concludes that all the Industry 4.0-related technologies

(BIM) as the most common technologies they have used. have been implemented and utilized. This data proves that

Identified in the mid-range (40– 60%) of the combined despite the even distribution of responses in FIG 2. It shows

technologies were Internet of things (IoT) that these innovative technologies listed as attained some

Modularization/Prefabrication, /Internet of Services (IoS), level of maturity within the construction industry.

Digitization, and Automation.

IJISRT23APR016 www.ijisrt.com 2448

Volume 8, Issue 4, April 2023 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

VII. CONCLUSION [5.] Carvalho, N., Chaim, O., Cazarini, E., &Gerolamo,

M. (2018). Manufacturing in the fourth industrial

IR 4.0 has been around for a while in the construction revolution: A positive prospect in sustainable

sector, and the technologies are at various stages of manufacturing. Procedia Manufacturing, 21, 671-

development. While other technologies like Augmented, 678.

Virtual, and Mixed Reality are still being developed and [6.] Hopali, E., &Vayvay, Ö. (2018). Industry 4.0 is the

might have an impact on the industry's sustainability, some last industrial revolution and its opportunities for

technologies like BIM, Cloud Computing, and developing countries. In Analyzing the Impacts of

Modularization have advanced greatly. Despite having Industry 4.0 in Modern Business Environments (pp.

access to these technologies, IR 4.0 adoption within the 65-80). IGI Global.

construction industry is still quite poor. The construction [7.] Hu, X., & Liu, C. (2016). Profitability performance

industry has adopted IR 4.0 methods, and the assessment in the Australian construction industry: a

implementation of these practices has resulted in major global relational two-stage DEA method.

effects across numerous platforms. However, the difficulties Construction management and economics, 34(3),

encountered must be resolved by all parties concerned to 147-159.

guarantee a successful implementation. The adoption of [8.] Keogh, M., & Smallwood, J. J. (2021, February). The

IR4.0 within the construction sector would boost role of the 4th Industrial Revolution (4IR) in

performance on par with that of its competitors in the enhancing performance within the construction

industrial and automotive sectors. industry. In IOP Conference Series: Earth and

Environmental Science (Vol. 654, No. 1, p. 012021).

VIII. RECOMMENDATION IOP

As was previously said, the lack of technical Publishing.https://www.researchgate.net/publication/

knowledge is a result of the construction industry's 349432796_The_role_of_the_4th_Industrial_Revolut

resistance to integrating Industry 4.0 technologies and going ion_4IR_in_enhancing_performance_within_the_con

through the digital transformation. Since the construction struction_industry. Retrieved 21-07-2022

sector is a complex ecosystem, more efforts from academics [9.] Lee, M., Yun, J. J., Pyka, A., Won, D., Kodama, F.,

and industry stakeholders are needed to adopt the new Schiuma, G., ... & Zhao, X. (2018). How to respond

concepts of the 4th Industrial revolution and push its to the fourth industrial revolution or the second

traditional boundaries. That is, employer associations, information technology revolution? Dynamic new

professional associations, and statutory councils should combinations between technology, market, and

increase public awareness of the potential application of society through open innovation. Journal of Open

Industry 4.0 in the construction industry; case studies should Innovation: Technology, Market, and Complexity,

be documented and the results shared; tertiary built 4(3), 21 http://dx.doi.org/10.3390/joitmc4030021.

environment education programs should integrate Industry Retrieved 21-07-2022

4.0 into all relevant modules, and continuing professional [10.] Oesterreich, T. D., &Teuteberg, F. (2016).

development (CPD) should address Industry 4.0. Understanding the implications of digitization and

automation in the context of Industry 4.0: A

REFERENCES triangulation approach and elements of a research

agenda for the construction industry. Computers in

[1.] Alaloul, W. S., Liew, M. S., Zawawi, N. A. W. A., & industry, 83, 121-139.

Kennedy, I. B. (2020). Industrial Revolution 4.0 in [11.] Philbeck, T., & Davis, N. (2018). THE FOURTH

the construction industry: Challenges and INDUSTRIAL REVOLUTION: SHAPING A NEW

opportunities for stakeholders. Ain shams engineering ERA. Journal of International Affairs, 72(1), 17–22.

journal, 11(1), 225-230. https://www.jstor.org/stable/26588339. Retrieved 21-

https://doi.org/10.1016/j.asej.2019.08.010. Retrieved 07-2022

21-07-2022 [12.] Taher, G. (2021). Industrial Revolution 4.0 in the

[2.] Alaloul, W. S., Liew, M. S., &Zawawi, N. (2016). Construction Industry: Challenges and Opportunities.

Coordination process in construction project Management Studies and Economic Systems, 6(3/4),

management. Engineering Challenges for a 109-127.

Sustainable Future, 149, 149-153. [13.] Turner, C. J., Oyekan, J., Stergioulas, L., & Griffin,

[3.] Bai, C., Dallasega, P., Orzes, G., &Sarkis, J. (2020). D. (2020). Utilizing industry 4.0 on the construction

Industry 4.0 technologies assessment: A sustainability site: Challenges and opportunities. IEEE

perspective. International journal of production Transactions on Industrial Informatics, 17(2), 746-

economics, 229, 107776. 756.

[4.] Colombo, A. W., Karnouskos, S., &Bangemann, T.

(2014). Towards the next generation of industrial

cyber-physical systems. In Industrial cloud-based

cyber-physical systems (pp. 1-22). Springer, Cham.

https://doi.org/10.1007/978-3-319-05624-1_1.

Retrieved 21-07-2022

IJISRT23APR016 www.ijisrt.com 2449

You might also like

- Digital Business Models in Industrial Ecosystems: Lessons Learned from Industry 4.0 Across EuropeFrom EverandDigital Business Models in Industrial Ecosystems: Lessons Learned from Industry 4.0 Across EuropeNo ratings yet

- Understanding Technological Innovation: Enabling the Bandwagon for Hydrogen TechnologyFrom EverandUnderstanding Technological Innovation: Enabling the Bandwagon for Hydrogen TechnologyNo ratings yet

- Industrial Revolution 40 in The Construction IndusDocument6 pagesIndustrial Revolution 40 in The Construction InduszeyadNo ratings yet

- A Study On Industry 4.0 Concept: Mr. Chaitanya Vijay BidnurDocument6 pagesA Study On Industry 4.0 Concept: Mr. Chaitanya Vijay Bidnurnouamane beghitiNo ratings yet

- Revolutionizing The Future of The Construction Industry: Strategizing and Redefining ChallengesDocument11 pagesRevolutionizing The Future of The Construction Industry: Strategizing and Redefining ChallengeszeyadNo ratings yet

- Buildings: Seunguk Na, Seokjae Heo, Sehee Han, Yoonsoo Shin and Youngsook RohDocument18 pagesBuildings: Seunguk Na, Seokjae Heo, Sehee Han, Yoonsoo Shin and Youngsook Rohhindray88No ratings yet

- Industry 4.0 Technologies and Their Impact in Contemporary Logistics: A Systematic Literature ReviewDocument27 pagesIndustry 4.0 Technologies and Their Impact in Contemporary Logistics: A Systematic Literature ReviewSooraj Kumar RNo ratings yet

- Industry Revolution IR 4.0: Future Opportunities and Challenges in Construction IndustryDocument7 pagesIndustry Revolution IR 4.0: Future Opportunities and Challenges in Construction IndustryZaihazra watyNo ratings yet

- 1 s2.0 S2452414X21000558 MainDocument19 pages1 s2.0 S2452414X21000558 MainIsac MartinsNo ratings yet

- Applied Sciences: Six-Gear Roadmap Towards The Smart FactoryDocument35 pagesApplied Sciences: Six-Gear Roadmap Towards The Smart FactorynaveedNo ratings yet

- IJRRS Volume 2 Issue 1 Pages 23-34Document12 pagesIJRRS Volume 2 Issue 1 Pages 23-34musawar420No ratings yet

- Technological Forecasting & Social Change: Tae Kyung SungDocument6 pagesTechnological Forecasting & Social Change: Tae Kyung SungEnd_06No ratings yet

- Industry 4.0, A Revolution That Requires Technology and National StrategiesDocument15 pagesIndustry 4.0, A Revolution That Requires Technology and National StrategiesWong Yong JieNo ratings yet

- Project UvDocument33 pagesProject UvYuvraj RoyNo ratings yet

- Industry 4 0 State of The Art and Future TrendsDocument23 pagesIndustry 4 0 State of The Art and Future TrendsitNo ratings yet

- The Applications of Industry 4.0 Technologies in Manufacturing Context: A Systematic Literature ReviewDocument34 pagesThe Applications of Industry 4.0 Technologies in Manufacturing Context: A Systematic Literature ReviewMimnun NNo ratings yet

- Exploiting Context-Aware Capabilities Over The Internet of Things For Industry 4.0 ApplicationsDocument8 pagesExploiting Context-Aware Capabilities Over The Internet of Things For Industry 4.0 ApplicationslazarNo ratings yet

- International Journal of Production Economics: Chunguang Bai, Patrick Dallasega, Guido Orzes, Joseph SarkisDocument15 pagesInternational Journal of Production Economics: Chunguang Bai, Patrick Dallasega, Guido Orzes, Joseph SarkisDiego AndradeNo ratings yet

- The Relationship Between The Implementation Levels of Industry 4.0 Technologies and Advanced Manufacturing TechnologiesDocument9 pagesThe Relationship Between The Implementation Levels of Industry 4.0 Technologies and Advanced Manufacturing TechnologiesaghowelNo ratings yet

- Applications of Industry 4.0Document31 pagesApplications of Industry 4.0bhargavNo ratings yet

- Industry 4.0 TechnologiesDocument34 pagesIndustry 4.0 Technologies08.reap-sendersNo ratings yet

- Logforum: Industry 4.0 and Its Impact On The Functioning of Supply ChainsDocument14 pagesLogforum: Industry 4.0 and Its Impact On The Functioning of Supply ChainsDiego NuñezNo ratings yet

- Construction 4.0 A Survey of Research TrendsDocument22 pagesConstruction 4.0 A Survey of Research TrendsNada GhanimNo ratings yet

- 4th Industrial Revolution Challenges and Opportunities in The South African ContextDocument7 pages4th Industrial Revolution Challenges and Opportunities in The South African ContextFerlan PangalilaNo ratings yet

- 1 s2.0 S0040162523000483 MainDocument16 pages1 s2.0 S0040162523000483 MainNhư GiaNo ratings yet

- 2019 - A Survey On Information and Communication Technologies For Industry 4.0 State-of-the-Art, Taxonomies, Perspectives and Challenges PDFDocument35 pages2019 - A Survey On Information and Communication Technologies For Industry 4.0 State-of-the-Art, Taxonomies, Perspectives and Challenges PDFchrisalexoNo ratings yet

- Industry 4.0 Operators: Core Knowledge and SkillsDocument7 pagesIndustry 4.0 Operators: Core Knowledge and SkillsDozo PowerNo ratings yet

- Good Linking-Digital-Technologies-To-Sustainability-Through-1v23v557Document20 pagesGood Linking-Digital-Technologies-To-Sustainability-Through-1v23v557secretary.alumniNo ratings yet

- The Future of Lean Construction in EthiopianDocument8 pagesThe Future of Lean Construction in EthiopianEDEN2203No ratings yet

- Task Eco Digital Business ResumeDocument3 pagesTask Eco Digital Business ResumeNovi IndrianiNo ratings yet

- ANNALS of Faculty Engineering Hunedoara - International Journal of EngineeringDocument6 pagesANNALS of Faculty Engineering Hunedoara - International Journal of Engineeringelif aslanNo ratings yet

- Construction 4.0, PLAN, Four Layer IntegrationDocument14 pagesConstruction 4.0, PLAN, Four Layer IntegrationNada GhanimNo ratings yet

- Industru - 5.0 - (Ισως να πω οτι η 5 ειναι προ των πθλων αλλα βασιζεται σε προλεψεις αρα δεν αξιζει να ερευνησω)Document9 pagesIndustru - 5.0 - (Ισως να πω οτι η 5 ειναι προ των πθλων αλλα βασιζεται σε προλεψεις αρα δεν αξιζει να ερευνησω)giwrgosdoulos22No ratings yet

- Direction of Industry A Literature Review On Industry 40Document10 pagesDirection of Industry A Literature Review On Industry 40Marko BrkicNo ratings yet

- Chinese Manufacturing Industry in The Context of IDocument6 pagesChinese Manufacturing Industry in The Context of Icc5csafety5No ratings yet

- Implementation of Industry 4 0 Concept in Companies Empirical Evidences PDFDocument19 pagesImplementation of Industry 4 0 Concept in Companies Empirical Evidences PDFMateo Cuadros HerreraNo ratings yet

- An Effect Analysis of Industry 4.0 To Higher Education: Mehmet Baygin, Hasan Yetis, Mehmet Karakose and Erhan AkinDocument4 pagesAn Effect Analysis of Industry 4.0 To Higher Education: Mehmet Baygin, Hasan Yetis, Mehmet Karakose and Erhan AkinFauzi RahmannullahNo ratings yet

- Impact of Industry 40 On Robotic WeldingDocument8 pagesImpact of Industry 40 On Robotic WeldinghebervaldoNo ratings yet

- Paper 1Document27 pagesPaper 1Thamizh Selvan SNo ratings yet

- Format For Reviewing ArticleDocument1 pageFormat For Reviewing ArticleMarial AsebiasNo ratings yet

- 2 67 1636194226 16ijmperddec202116Document18 pages2 67 1636194226 16ijmperddec202116TJPRC PublicationsNo ratings yet

- s11356 022 24764 1Document16 pagess11356 022 24764 1Hanis SuzanaNo ratings yet

- Hamzeh Et Al. 2021 - Lean Construction 4.0 - Exploring The Challenges of Development in The AEC IndustryDocument10 pagesHamzeh Et Al. 2021 - Lean Construction 4.0 - Exploring The Challenges of Development in The AEC IndustryFgNo ratings yet

- Applied Sciences: Industry 4.0 For The Construction Industry-How Ready Is The Industry?Document26 pagesApplied Sciences: Industry 4.0 For The Construction Industry-How Ready Is The Industry?Arie UdienNo ratings yet

- Industry 4.0 Adoption Challenges and Benefits For SMEsDocument12 pagesIndustry 4.0 Adoption Challenges and Benefits For SMEsRakshith SNo ratings yet

- Preprints202006 0007 v1 PDFDocument68 pagesPreprints202006 0007 v1 PDFercanNo ratings yet

- 672-Article Text-9357-1-10-20220125Document7 pages672-Article Text-9357-1-10-20220125mr.steve.obiNo ratings yet

- Industry 4.0 3Document6 pagesIndustry 4.0 3Mandhara KsNo ratings yet

- Economies: Industry 4.0 For The Construction Industry: Review of Management PerspectiveDocument14 pagesEconomies: Industry 4.0 For The Construction Industry: Review of Management Perspectivejiasing LohNo ratings yet

- A Study On Influence of Industry 4.0 in The Domestic, Industrial and Transportation SectorDocument3 pagesA Study On Influence of Industry 4.0 in The Domestic, Industrial and Transportation Sectordeepika snehiNo ratings yet

- Productive Technologies For Industry 4.0: PreprintDocument9 pagesProductive Technologies For Industry 4.0: Preprintsaffuan saadNo ratings yet

- Additive Manufacturing Applications in Industry 4.0: A ReviewDocument23 pagesAdditive Manufacturing Applications in Industry 4.0: A ReviewAnndava SubashNo ratings yet

- Technical Considerations For The Conformation of Specific Com-Petences in Mechatronic Engineers in The Context of Industry 4.0 and 5.0Document46 pagesTechnical Considerations For The Conformation of Specific Com-Petences in Mechatronic Engineers in The Context of Industry 4.0 and 5.0VeLuisNo ratings yet

- The Road To Industry 4.0 and Beyond: A Communications-, Information-, and Operation Technology Collaboration PerspectiveDocument7 pagesThe Road To Industry 4.0 and Beyond: A Communications-, Information-, and Operation Technology Collaboration PerspectivePedrito OrangeNo ratings yet

- Impact of Industry 4.0 Platform On The Formation of Construction 4.0 Concept: A Literature ReviewDocument15 pagesImpact of Industry 4.0 Platform On The Formation of Construction 4.0 Concept: A Literature ReviewAkim FrankNo ratings yet

- IR 4.0 and Various SectorsDocument44 pagesIR 4.0 and Various SectorsThejaswiniHPNo ratings yet

- Industry 4.0: An Overview: July 2018Document7 pagesIndustry 4.0: An Overview: July 2018Steve StevenNo ratings yet

- Seminar Report (Industry 4.0)Document24 pagesSeminar Report (Industry 4.0)Vaibhav BhosaleNo ratings yet

- The Biometric Industry Report - Forecasts and Analysis to 2006From EverandThe Biometric Industry Report - Forecasts and Analysis to 2006M LockieNo ratings yet

- Factors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaDocument6 pagesFactors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Study Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoDocument6 pagesStudy Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Unmasking Phishing Threats Through Cutting-Edge Machine LearningDocument8 pagesUnmasking Phishing Threats Through Cutting-Edge Machine LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Industry That Capitalizes Off of Women's Insecurities?Document8 pagesAn Industry That Capitalizes Off of Women's Insecurities?International Journal of Innovative Science and Research TechnologyNo ratings yet

- Blockchain Based Decentralized ApplicationDocument7 pagesBlockchain Based Decentralized ApplicationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Cyber Security Awareness and Educational Outcomes of Grade 4 LearnersDocument33 pagesCyber Security Awareness and Educational Outcomes of Grade 4 LearnersInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Insights Into Nipah Virus: A Review of Epidemiology, Pathogenesis, and Therapeutic AdvancesDocument8 pagesInsights Into Nipah Virus: A Review of Epidemiology, Pathogenesis, and Therapeutic AdvancesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Parastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueDocument2 pagesParastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Smart Health Care SystemDocument8 pagesSmart Health Care SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Smart Cities: Boosting Economic Growth Through Innovation and EfficiencyDocument19 pagesSmart Cities: Boosting Economic Growth Through Innovation and EfficiencyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Impact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldDocument6 pagesImpact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Diabetic Retinopathy Stage Detection Using CNN and Inception V3Document9 pagesDiabetic Retinopathy Stage Detection Using CNN and Inception V3International Journal of Innovative Science and Research TechnologyNo ratings yet

- Visual Water: An Integration of App and Web To Understand Chemical ElementsDocument5 pagesVisual Water: An Integration of App and Web To Understand Chemical ElementsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Compact and Wearable Ventilator System For Enhanced Patient CareDocument4 pagesCompact and Wearable Ventilator System For Enhanced Patient CareInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Harnessing Open Innovation For Translating Global Languages Into Indian LanuagesDocument7 pagesHarnessing Open Innovation For Translating Global Languages Into Indian LanuagesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Air Quality Index Prediction Using Bi-LSTMDocument8 pagesAir Quality Index Prediction Using Bi-LSTMInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Predict The Heart Attack Possibilities Using Machine LearningDocument2 pagesPredict The Heart Attack Possibilities Using Machine LearningInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Keywords:-Ibadhy Chooranam, Cataract, Kann Kasam,: Siddha Medicine, Kann NoigalDocument7 pagesKeywords:-Ibadhy Chooranam, Cataract, Kann Kasam,: Siddha Medicine, Kann NoigalInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- An Analysis On Mental Health Issues Among IndividualsDocument6 pagesAn Analysis On Mental Health Issues Among IndividualsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Parkinson's Detection Using Voice Features and Spiral DrawingsDocument5 pagesParkinson's Detection Using Voice Features and Spiral DrawingsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Relationship Between Teacher Reflective Practice and Students Engagement in The Public Elementary SchoolDocument31 pagesThe Relationship Between Teacher Reflective Practice and Students Engagement in The Public Elementary SchoolInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Making of Object Recognition Eyeglasses For The Visually Impaired Using Image AIDocument6 pagesThe Making of Object Recognition Eyeglasses For The Visually Impaired Using Image AIInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Advancing Healthcare Predictions: Harnessing Machine Learning For Accurate Health Index PrognosisDocument8 pagesAdvancing Healthcare Predictions: Harnessing Machine Learning For Accurate Health Index PrognosisInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Implications of Adnexal Invasions in Primary Extramammary Paget's Disease: A Systematic ReviewDocument6 pagesImplications of Adnexal Invasions in Primary Extramammary Paget's Disease: A Systematic ReviewInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Investigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatDocument16 pagesInvestigating Factors Influencing Employee Absenteeism: A Case Study of Secondary Schools in MuscatInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)Document2 pagesDense Wavelength Division Multiplexing (DWDM) in IT Networks: A Leap Beyond Synchronous Digital Hierarchy (SDH)International Journal of Innovative Science and Research TechnologyNo ratings yet

- The Utilization of Date Palm (Phoenix Dactylifera) Leaf Fiber As A Main Component in Making An Improvised Water FilterDocument11 pagesThe Utilization of Date Palm (Phoenix Dactylifera) Leaf Fiber As A Main Component in Making An Improvised Water FilterInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Formulation and Evaluation of Poly Herbal Body ScrubDocument6 pagesFormulation and Evaluation of Poly Herbal Body ScrubInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Terracing As An Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains - CameroonDocument14 pagesTerracing As An Old-Style Scheme of Soil Water Preservation in Djingliya-Mandara Mountains - CameroonInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- The Impact of Digital Marketing Dimensions On Customer SatisfactionDocument6 pagesThe Impact of Digital Marketing Dimensions On Customer SatisfactionInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- 001 Week 3Document3 pages001 Week 3Rusty Ugay LumbresNo ratings yet

- Q1-1. Consumer HealthDocument35 pagesQ1-1. Consumer HealthMaven JadeNo ratings yet

- Annual Average Daily Traffic Estimation From Seasonal Traffic CountsDocument13 pagesAnnual Average Daily Traffic Estimation From Seasonal Traffic CountsSantosh HiredesaiNo ratings yet

- Scientific Method PPTDocument35 pagesScientific Method PPTGaukhar IlashevaNo ratings yet

- ECO242Document1 pageECO242cibeneche07No ratings yet

- Worldmaking After Empire: The Rise and Fall of Self-DeterminationDocument10 pagesWorldmaking After Empire: The Rise and Fall of Self-Determinationmilica.starinacNo ratings yet

- To Inform: Yasmiene B. Daprosa 9-FaradayDocument1 pageTo Inform: Yasmiene B. Daprosa 9-FaradayYasmiene DaprosaNo ratings yet

- Race To InnocenceDocument10 pagesRace To Innocencem2xnwsvjyjNo ratings yet

- Motivasi Kerja SkalaDocument12 pagesMotivasi Kerja Skalacitra Resmi wulandariNo ratings yet

- Sign Language Translator Presentation - IIDocument26 pagesSign Language Translator Presentation - IIAman BindNo ratings yet

- ASCD UBD WhitepaperDocument15 pagesASCD UBD WhitepaperLukluul MaknuunNo ratings yet

- Evans HistoricismPostmodernismHistoriography 2002Document10 pagesEvans HistoricismPostmodernismHistoriography 2002solomon GebreNo ratings yet

- Shiv Final Report PDFDocument26 pagesShiv Final Report PDFapeksha SiddramNo ratings yet

- Bsaf 1Document8 pagesBsaf 1Yahiya ObaidNo ratings yet

- La3025 Vle PDFDocument182 pagesLa3025 Vle PDFRaquel Zoe BirsaNo ratings yet

- Acin 2016 Certified Randomness in Quantum PhyDocument18 pagesAcin 2016 Certified Randomness in Quantum PhyTaNiTa TiKaRaNNo ratings yet

- Plan Anual de Tercero InglésDocument8 pagesPlan Anual de Tercero InglésAbigail Sisalema BastidasNo ratings yet

- King's College of The Philippines Bambang Campus Prof Ed Examination Name: - Date: - Course&Yr: - I. Multiple Choice: Encircle The Best AnswerDocument8 pagesKing's College of The Philippines Bambang Campus Prof Ed Examination Name: - Date: - Course&Yr: - I. Multiple Choice: Encircle The Best AnswerRainer Arthur LarocoNo ratings yet

- Committe Details New 2021Document10 pagesCommitte Details New 2021Nikhil GuptaNo ratings yet

- Project Proposal - Seminar On Public SpeakingDocument2 pagesProject Proposal - Seminar On Public SpeakingAngelo FaustinoNo ratings yet

- UXR - Data AnalysisDocument12 pagesUXR - Data AnalysisfentyemaNo ratings yet

- Samuel and Bryant's (1984)Document5 pagesSamuel and Bryant's (1984)pradaguccidiorNo ratings yet

- Erikson - 8 Stages of Human DevelopmentDocument5 pagesErikson - 8 Stages of Human DevelopmentKavitha AlwisNo ratings yet

- MODULE 11 Gagne's Conditions of LearningDocument16 pagesMODULE 11 Gagne's Conditions of LearningTrisha MirandaNo ratings yet

- Data Science Internship Summary Presentation: Vikas Gupta June 2021Document27 pagesData Science Internship Summary Presentation: Vikas Gupta June 2021Vikas Gupta100% (1)

- 2023 Spring - 2232 Psyc 4327 001Document8 pages2023 Spring - 2232 Psyc 4327 001Sarah NwosuNo ratings yet

- ZZZ Incumbent-Newcomer CombineAllDocument102 pagesZZZ Incumbent-Newcomer CombineAllVictor LAU (MGT)No ratings yet

- TF, CF, Sop, RHDocument6 pagesTF, CF, Sop, RHJewel SebastianNo ratings yet

- Contrastive Analysis, Error Analysis, InterlanguageDocument22 pagesContrastive Analysis, Error Analysis, Interlanguagesong duaNo ratings yet

- Principles of Teaching Quiz 2Document3 pagesPrinciples of Teaching Quiz 2Alona MarieNo ratings yet